In this article, we talk about role of nanotechnology in mechanical engineering and the application of nanotechnology in mechanical engineering field.

Table of content

- Nanoscale thermal-eletrical transporter

- Nano-thermo physical engineering

- Adavanced micro and nano-mechanical Material and process technology

- Nano-materials in mechanical side

- Nanotechnology used to manage the corrosion of steel

- Current and future Developement

Introduction of nanotechnology

First questions in your mind, Whats nanotechnology concern with mechanical engineering.

Here the answers about nanotechnology, nanomaterial is used in the mechanical engineering, to increase quality of the product or efficiency of the product.

Nanofield include subfield of nanofield in which develope or study material which has unique properties.

Interface and colloid science used in many fabric which is also useful for nanotechnology.

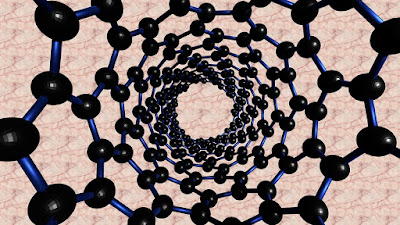

Such as carbon nanotube and other fullerenes and various nanoparticle and nanorods.

Nanomatarial with fast ion transport are related to also nanoionics and nanoeletronics.

Nanomaterial used for bulk product, most present application of nanotechnology, used in medical applications.

Nanomaterial used in the solar cell which reduce the cost of the silicon solar cells.

Semiconductor nanoparticle is used in the next generation products such as display technology , solar cell, lighting, and biological imaging.

Nanotechnolgy research in mechanical engineering

Nanotechnology also use in the mechanical engineering. Nanoscale machines which work on the molecular or even atomic level which gives the new level of quality to the product.

When the nanoscale submarie kill the cancer cell, one cell at time. Nano particle form a product in molecular level or atomic level.

Already research show that flow around micro-scopic level is laminar.

Nanoscale Thermal-Electrical trasport

Thermal and Electrical Small scale energy means that nanoscale strong effect on the many devices.

For example, direct energy conversion heat sink and field-effect transistor. Thermo-lab are study on these type of material on nanoscale.

Carbon nanotube is example of the nanotechnolgy in the mechanical engineering study in the thermo-lab.

Thermo-lab activities include detailed experimental and computational studies synthesis by plasma-enhanced chemical vapor depostion.

With application to single wall carbon nanotube transistors and multi-wall carbon nanotube used to enhanced the thermal or electrical interface conductance, boil heat transfer and boisense performance.

Futher lab has developed unique capabilities to measure and model thermal-electrical energy, transport and conversion from nanoscale electron emitters.

Thermal micro/nanosystem

Thermal transfer getting more popular in the invention and Performance of micro-and nano system.

Inquire in this region, include the developement range of micropumping appoarches and high-resolution measurement techniques.

For example, evalutions of a micromechanical electrohydrodynamics based liquid pump with multiple driving mechanisms to drive high flow rate and ionic wind-driven heat transfer enhancement scheme.

other filed research including microscale actuations of liquid using electrowetting and dieelectrophoresis, thin film evaporation.

single and two-phase microchannel transport and evalution of carbon nanotube based heat spreaders.

Nano Thermo-physical engineering

The behavior of any phsyical system can be connected to the atomicscale. With an atomic level knowledge of the energy carrier (photon, electron, phoning, and fluid particle ) charateristics and behaviors, one able to prompt upward to design nano and micro structure with desired size effect.

Research at the nanothermo-physical engineering, lab seek to build up and expand the understanding fundamental of atomic level carrier transport.

And intereaction and to apply this knowledge to important energy and information technology.

Current project including the applied science electron-phonon coupling quantum dot solar cell.

Enhanced laser cooling of semiconductor and ion-doped solids.

controlled thermal emission using modulate micro and nano-structure.

thermo-optical management of nano-laser and so on.

Advance micro-nano mechanical matarials and process technology

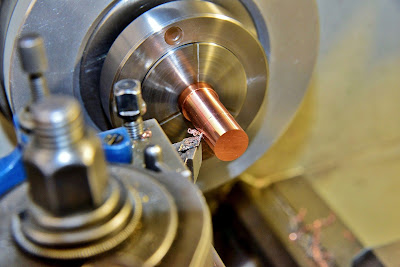

Now days in the manufacturing industries, material selection is in micro-nano system.

These application has been relatively limited due to micro frabrication process and infrastucture dedicate to silicon.

While silicon has proven that to be perfect for the many applications. So no single material can match the demand of whole application material.

Research in this area, seek to get materials and process technologies need for realization of application that either imparticle or impossible conventional silicon-based microtechnology.

For example biomedical and harsh enviroment applications.

In this area of study, presently under developement including antisotropic titanium micromachining microchemical composite and nevol application thereof.

Nanomaterial in mechanical side

We can define nanomaterial which have nanostructured component with at (less than 100nm).

Material with one diamension in the nanoscale are layers such as thin films or surface coatings.

Fabrics that are nanoscale in two diamensions are nonwires and nanotubes.

Material that are nanoscale in three diamensions particles and quantum dots (tiny specks of semiconductor material).

Nanocrystilline material, prepare up of nanometer-sized textures, also fall into this class.

Two main factors have the properties of nanomaterial to differ signficantly from other material.

Increased relative surface area and quantum effects. These genes can modify or enhanced properties.

Such as responsiveness, strenght and electrical properties , optical characteristics.

Nanotechnology used to manage the corrosion of steel

Over the last two decaded, significant advancement has been made to improve the management of steel corrion through research, developement and implementation.

Nanotechnolgy has been playing an increasing important role in supporting innovative technology advance.

Nanotechnology is used in corrosion resistance and carrying out of the soul itself.

By reaching the finely crystalline micr-level structure of steel(e.g nancrystallization). By changing its chemical composition at the nanometer level.

For example formation of copper nanoparticle at the steel gain boundaries.

Metallurgy approach to the production of high performance steel with fine grain structure.

And self-organization of strenghting the nano phases (carbides, nitrides , carbon nitrides, inter metallides) have used nanotechnology principle and process.

Such as nanoprocess for steel smelting and micro-alloying, mechanical pressure treatment and high pressure treatment.

Nanotechnology has been used to thin out the corrosion envinroment through the alternation of steel interfence.

For example formation nanocomposite thin coating films on the steel.

Advance in corrosion protection of the steel have been reported to the co-deposition of Ni-SiC or Al2O3 nanocomposite on mild steel.

Application of the TiO2-nanoparticle so gel coating or multilayer polyelectrolyte nanoflims on 316L stainless steel.

The Incorportions of nano-sized molecules (e.g polyaniline/ferrite, ZnO, Fe2O3, hallosite clay, and other nanoparticle) into convenational polymer coating.

Conventional polymer coating also significantly raised anticorrosion performance of such coating on steel subtractes.

Incorportion of a nanoparticle in ceramic coatings, polymer coatings, and hybride so-gel coatings system for improved properties.

For example resistance to corrosion and high temperature oxidations self ceaning and anti-fouling.

Current and future Developement

Nano-technology has shown its clear benefits and continue to take on central part in the production of high performance of steel.

Future developements concentrated on encouraging the understanding way and how supperior corrosion resistance of steel can be achieved by the design and control of its chemical compositions.

And morphology at the micro and nano-meter scale.

E.g through microalloying and thermal mechanical treatment.

progress in steel production technology will open the possibilties of rapid change in the steel metallurgy and increase the competitiveness of nano-enable products.

Nanotechnology has made for fundamental changes to the methods of mitigating corrosion risk at steel/electrolyte interface.

Future developments will go forward in the technologies that can produce altra thin ceramic or metallic nano composite level or nano crystalline layer on steel.

For example, physical vapour deposition, chemical vapour depostions, ion-implantation sol-gel applications and electro-depositions.

More innovations can be required in the incoportion of nano-particle in ceramic coating, polymer coating, and hybrid sol-gel system for enhance corrosion of blade and other metallic substrates.

Incoming years, much more attention will be paid for the uses of the nanotechnology in intelligent corrosion protection systems.

New area of application would be the role of nano-sized reservoir in the self heating coatings.

Even though current research has been confined to micro-size capsules. Another increasingly active field would be the use of functionalized an nanoparticle as innovation carries of corrosion inhibitors in coating.

Since nano particle feature high surface area can be engineered for smart delivery of corrosion inhibitors.

Conclusion

Mechanical engineering over the succeeding two decades will be called upon to produce technology.

That foaster fairer, healthier, more dependable sustainable goble environment.

Nanotechnology is dominated technological development in the next 20 year.

And will be integrate into all aspects of technology that involve our spirit daily base.

Nanotechnology provide a building blocks that future engineering will pratice to solve pressing problems in various area.

Problem include medical, energy, water mangement, aeronautics, farming and environmental mangement.

Equally its turning more and more obvious that nanotechnologies lie at the centre of technology invention.

Many great opportunities lie in the crossroad of this technology. Mechanical engineering turn the filed to draw into safer world positions.