What Is A Screw?

Screw is a type of fastener which is mostly made of metals of different nature. By engaging the screw thread with a required internal thread inside the matching part, screws and bolts are also used to fasten materials.

Generally screws are self-threading, also known as self-tapping screws, cut into the material as they are turned, producing an internal thread that plays an important role in dragging materials together and prevents pullout. For various materials, there are various screws available:

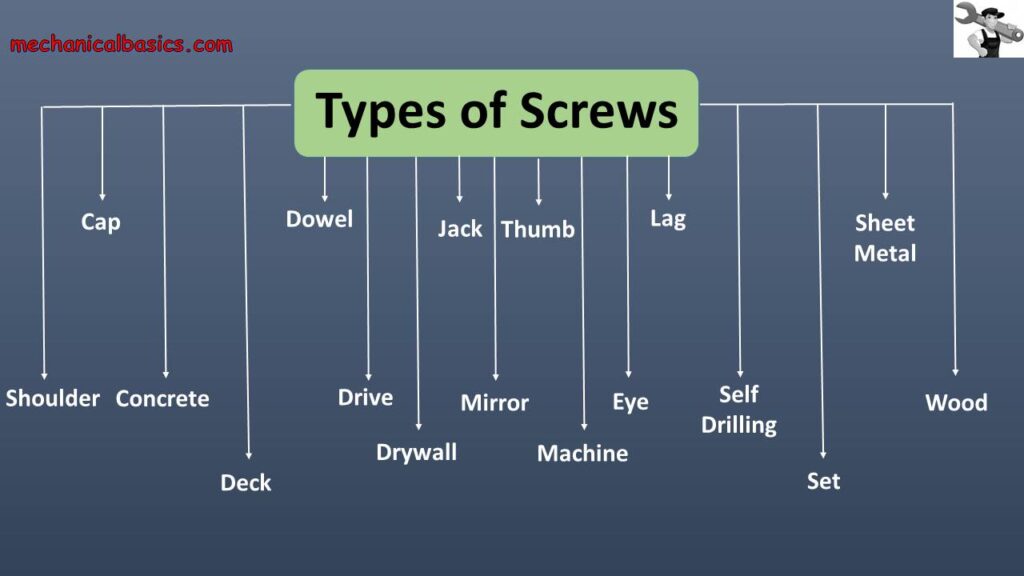

Types of Screws

-

- Wood screws

-

- Cap screws

-

- Deck screws

-

- Dowel screws

-

- Drive screws

-

- Drywall screws

-

- Eye screws

-

- Jack screws

-

- Lag screws

-

- Concrete screws

-

- Machine screws

-

- Mirror screws

-

- Self-drilling screws

-

- Set screws

-

- Sheet metal screws

-

- Shoulder screws

-

- Thumb screws

-

- Wing screws

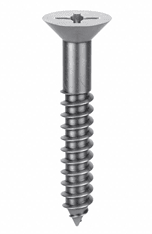

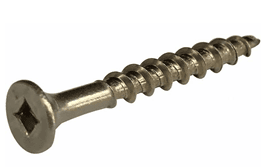

Wood Screws

A wood screw is a typical type of screw that is made of

Digging into wood to secure wooden components is a pretty simple process. As we approach the screw head, it becomes a little more tapered. The screw’s diameter is larger than the tip. Both partially and fully covered threads are available for the shank.

They are mostly used for wooden applications and are quite handy for fastening wooden items of work. Various applications will determine how this screw’s head will be shaped.

Cap Screws

A cap screw is generally used without a nut and is tightened directly into a threaded or tapped hole.

Its cylindrical shaft features an external thread with a helical shape that allows the screw to advance when rotated.

It has a big head on one end and a cylindrical shaft. The internal thread of the tapped hole is the same as the screw’s external thread.

This screw moves forward when it is inserted and turned into a tapped hole. Tightening and loosening the screw is performed by applying torque to the screw head with a tool.

There are multiple cap screw heads available, so various tools can be used to tighten or loosen the screw.

Deck Screws

Deck screws are a type of wood screw that is specifically developed for outdoor use and to hold soft or hardwood decking in place as it flexes while people walk on it.

In order to hold the board firmly and prevent them from sinking into the wood and splitting it, deck screws have a larger head surface.

The upper part of the shank is usually smooth, and the threading is deep, pointed, and tapering toward the tip for cutting into the wood and gripping it. The screw will hold deck boards snugly to the under frame and is strong with a better load-bearing capacity.

Some deck screws feature split threads at the tip for easier driving and a quicker first bite into the wood, while others have inverse threading on the upper shank to stop the decking from mushrooming.

Dowel Screws

Lag threaded dowels (studs) are used as dowel screws to join two pieces of wood together. They are double-ended, headless screws that resemble standard studs but contain wood screw threads on both ends.

Dowel screws are made with rough, evenly spaced threads that taper to a blunt point and are used to start threading into a pilot hole of the right size. Since they are thread-forming screws, they do not require nuts or tapped holes to install; instead, they produce their unique mating threads in the wood.

Install the screw by rotating it clockwise because both ends have conventional right-hand threading.

Locking pliers can be used without harming threads thanks to an unthreaded body piece known as a “simple centre.”

Drive Screws

Drive screws are powerful and long-lasting for long-lasting strength. They are also known as U-drive screws, Un-slotted round head screws or Hammer drive screws.

Un-slotted heads, round, multiple start threads with wide helical angles, and an unthreaded pilot point characteristic drive screws.

A mallet, hammer, or other hammer-drive tool is used to drive hammer drive screws into mating components, much like nails, to facilitate fast and reliable assembly.

The mating part does not need to have any tapping threads, but it does need a pre-drilled pilot hole that is too small, and the U-drive screw needs to be manufactured of a material that is more durable than the matching parts.

For use in heavy-duty fastening applications, drive screws are designed. For attaching nameplates, wall signage, and other similar purposes, hammer drive screws are frequently utilized.

Drywall Screws

Drywall screws can have fine or coarse threads; the more threads a screw has, the “finer” the threads appear to be when you look at the screw.

Drywall screws, with their thin shanks and big heads, drive easily and rapidly through drywall to the wood or metal stud behind it.

When attaching drywall to wood studs, W-type drywall screws are utilized because they have coarser threads; by comparison, S-type drywall screws have finer threads and are used when attaching drywall to metal studs. G-type drywall screws contain fine threads as well, to but alternate between high and low thread heights. They are used to adhere drywall to drywall.

Drywall screws have a special bugle-shaped head that makes a smooth curve between the shank and the bottom of the head, which is one of their most recognizable features.

This enables them to press into the face paper of the drywall and produce a small depression without damaging the paper, which would reduce the screw’s ability to hold. During the drywall finishing process, the depression is filled with joint compound to provide a flawlessly smooth surface.

Eye Screws

A screw that has one end that is curved into a loop rather than being flat is known as an eye screw, also known as a screw eye for an eye bolt.

The threads of a standard screw are the revolving wavy lines that curve around the screw and enable it to go into materials more quickly.

A traditional screw has a flat end with an indentation for the screwdriver to be inserted into, while the other end is made up of the threads of the screw.

The top of the eye screw is flat; the other end is threaded. The screw’s bent end, on the other hand, creates a wide circle. An eye screw has the benefit of being quick to and allowing the user to hang items from it.

It can be used to hang a picture on a wall, join two pieces of material together, or both. Additionally, they are used to connect wires for supporting items.

Jack Screws

Jack screw is also referred to as Screw Jack. One of the most famous ones of motion control actuators that used move or lift loads is the jackscrew.

It can also be implemented in situations where linear motion is necessary or if a vehicle needs to be pulled or pushed along a linear axis. Simple mechanical actuators include screws with a lead, ball, or socket head.

The terms “spindle” or “spindle jack” refer to a jack that rotates a spindle. Medium to heavy weights and automobiles are frequently lifted using this method. The most common sort of jack screw is the classic hand type, which raises or lowers the load by exerting pressure on a lever to lift the screw from the unit’s base.

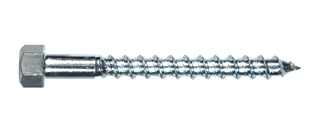

Lag Screws

Some of the strongest types of screws are lag screws. Lag screws, which are also known as lag bolts, are frequently used to join heavy hardwood as well as other materials that must support a strong weight.

These screws are distinct from more typical ones like

While some screws’ overlap with those of other screws, each screw serves a distinct purpose.

You must first drill a hole in order to use lag screws. Additionally, lag screws use a nut on one side of the screw to try and hold things together; the snug fit of the wood screw eliminates the need for a nut.

On the other hand, wood screws can’t even handle the same weights as lag screws because they are often smaller and don’t use nuts. Sheet metal screws, that have threads running the length of the shaft, are distinct both from wood screws and lag screws.

You need to use a ratchet or nut driver to insert a screw with a hex head. When a lot of torque is needed, hex heads are required. As for other sorts of heads, it depends on the drive whether they can be used with a variety of drivers. Others have Philips heads, while others have slotted heads. One exception are Torx drive screws.

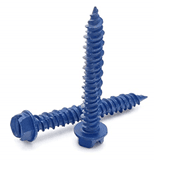

Concrete Screws

Concrete, mortar joints, concrete block, and brick are all examples of masonry, and concrete screws are specifically made to have their threads tap into a pre-drilled hole in masonry.

These screws have two leads, a raised and lowered thread pattern that alternates, notches in the raised threads, and a diamond-shaped nail-like point. There is no requirement for an anchor pre-set in the substrate because the design is perfect for their intended usage—for use in light or medium-duty applications.

The screws are case hardened to increase thread strength while preventing the body of the screw from becoming too brittle to cause the head to break off while driving into hard masonry.

Once installed, these screws can be easily withdrawn. However, it is not advised to use the screw again in the same hole due to thread wear that causes a reduction in grip strength or a complete loss of grip strength.

Machine Screws

In early clocks and weapons, machine screws were the first parallel threaded driving screws. It was the king of fasteners in the early 1900s and the most widely used, least expensive, and low-grade screw.

In the previous 100 years, the machine screw has seen several changes; the threads are now rolled rather than cut, unless the screws are really small or the amounts are low volume and not chosen. With the exception of micro-screws, screw heads and drivers are once again cold forged.

The most popular head types for machine screws are Pan and Counter-sunk, though a wide variety of head types are available. Machine screws are available in a wide range of driver and head types.

These include

-

- Security heads (which are simple to assemble but challenging to remove)

-

- Square-drive socket heads

Low tensile steel is the primary material used to create machine screws, but they can also be found in brass, aluminium, and stainless steel.

Machine screws serve a variety of purposes in phones, electrical appliances, electronic gadgets, and cars in addition to being used to secure parts to machines and mechanical tools.

Mirror Screws

The best way to attach mirrors to any wall is with mirror screws. Decorative items like mirrors, glass, and panel are using mirror screws. They offer a safe and attractive fixing for vanity mirrors, access panels, splash backs, and other thin panels when used in conjunction with mirror screw caps.

They have a flat head so they can hold the mirror firmly in place and sit flush to the mirror, providing a neat, attractive finish. Mirror screws are perfect for securing access panels that must be opened regularly or rapidly in the event of an emergency because they make it easy to remove the mirror or panel.

Self- drilling Screws

The self-drilling screws have the additional benefit of being made from strong stainless steel, which resists rust and corrosion. It is simple to install these in a pre-drilled hole and they are typically utilised in sheet metals. Additionally, these screws have the ability to cut machine threads.

They are suitable for a variety of applications, including industrial and construction, due to their many configurations. Additionally, these are commonly utilized in the constriction of metal, wood, and brick.

However, you must ensure that the hole is not too large, since the screw will have nothing to grab on to or stay attached to, especially if the material is soft, such as some types of wood.

Set Screws

Set screw also known as grub screw. It is used to strengthen the security of an object and may be combined to another object or attached from within. It stands out from other screws due to its headless body.

Throughout all of its body, in several dimensions, you can see mechanical threads. During the screw installation and good fastening, it is necessary to maintain an internal twisting drive.

As long as there is clamping force exerted to the object’s complete body, you may be confident it won’t slip off once it is attached.

The best feature about installing is that you may reuse it without breaking the threads and maintaining the thread’s surface corrosion-proof. Both soft and hard surfaces are suitable for applying these fasteners.

Sheet – metal Screws

A specific type fastener made for use with sheet metal is called a sheet metal screw. Exterior threading that spans the full shank is a defining feature of sheet metal screws. A regular screw’s shank is only partially covered with outside threading, as can be observed if you look at this. The outside threading does not start until midway of the screw’s shank.

The shank of sheet metal screws is fully covered with external threading, trying to set them apart from ordinary screws.

The mechanism of sheet metal screws is a completely threaded shank that digs into the metal.

A common screw can be challenging to drive into sheet metal, or even impossible in some situations. Like ordinary screws, they don’t get “hang up” at the entry point. They can be installed quickly and easily because of their threaded shank.

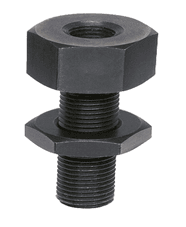

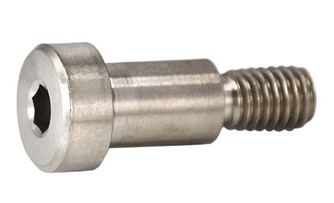

Shoulder Screws

A shoulder screw, generally known as a shoulder bolt, has a shank that “steps down” in diameter for the threaded length from a larger diameter just below the head.

A “shoulder” that can be tightly tightened against the component to which is screwed is created by the change in diameter.

In order to give the other part axial clearance, this enables a shoulder screw to be securely connected to one side without clamping it.

In order to connect the parts with a pin joint, the shank gives a smooth bearing surface. Different head types may be used with shoulder screws. Although ordinary hex heads can be used, hex socket cap heads are more popular.

Although shoulder screws can be available in normal sizes, it is rather common for them to be custom parts dimensioned for a certain machine. There is typically an undercut between the shoulder and the beginning of the thread in addition to the step between the thread diameter and the shank diameter. A threaded hole can be reached by tightly screwing the shoulder up to this undercut.

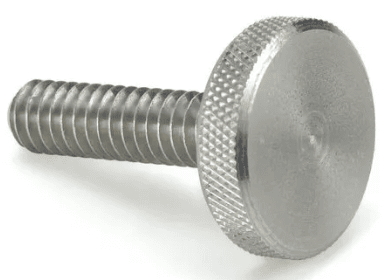

Thumb screws

Thumb screws can have a vertical head with flat sides, a wing, a tall head, knurled sides, or any combination of these. The head of the thumb screw can rest flush on the mating surface due to the shoulder arrangement. Thumb screws include a hand-adjustment function that makes it easy to tighten, loosen, secure, or remove the screws.

The main advantage is that no tools are required; assembly teams and end users may adjust the screws with just their thumb and fingers. Almost mainly thumb screws are used for the sake of simplicity. However, they are also perfect for instances where there is not enough room for tools to be used to fasten the screw.

Thumb screws can cut down on the time needed for maintenance or inspection when utilized for applications that need removal and reinstallation, like safety covers or access panels.

As a result of less frequent removal and reinstallation, their hand-adjustment design also lowers the risk of damaged or stripped fasteners. Thumb screws are not suggested for construction purposes or high-vibration settings, such as

-

- Marine vehicles, where cyclical loading may cause them to become loose over time.

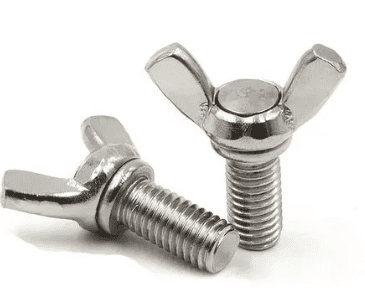

Wing Screws

To allow users to make direct changes and modify calibrations, wing screws are typically utilized in construction applications. On the side of these screws are flat protrusions known as the “head.”

This offers natural turning leverage, ensures that finger pressure is evenly distributed, and prevents pain while changing an instrument. These screws are available in a variety of sizes to fulfill all of your fastening requirements. In order to ensure that it is strong and corrosion-resistant, it is also composed of stainless steel, alloy steel, and carbon steel elements. Additional advantages of these screws are the simple installation procedure that can be used to set them up. It does not require any specific assembly and is hence generally utilized in consumer products because it can be constructed fast.