Introduction to Coreless Induction Furnace

Coreless induction furnaces represent a significant advancement in metal melting technology, offering unprecedented efficiency and precision in metallurgical processes. These furnaces utilize electromagnetic induction to heat and melt metal, revolutionizing the foundry and metal processing industries. As we delve into the intricacies of this technology, we’ll explore its principles, applications, and the profound impact it has on modern manufacturing.

Principles of Coreless Induction Furnace are:

1. Electromagnetic induction

2. The joule effect

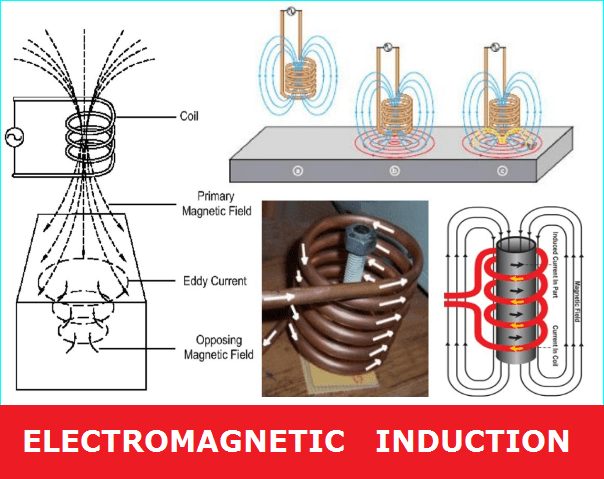

Electromagnetic induction

Electromagnetic induction transfers energy to the material to be heated. In a variable magnetic field, any electrically conductive material is a place with which induces electrical currents, called eddy currents, eventually contributing to Joule heating.

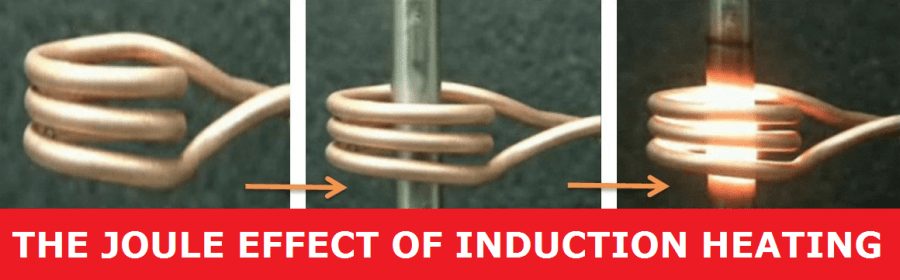

The joule effect

Joule heating is however known as ohmic heating or resistive heating, which is the procedure used to release heat through a conductor by the transmission of electric current. The amount of heat generated is proportional to the square of the current times the wire’s electrical resistance.

At the heart of coreless induction furnace technology lies the principle of electromagnetic induction, first discovered by Michael Faraday in 1831. This phenomenon occurs when a changing magnetic field induces an electric current in a conductive material. In the context of induction furnaces, this principle is harnessed to generate heat directly within the metal charge.

Types of Induction Furnace:

The induction furnace seems to be an electric furnace wherein the heat is supplied with metal induction heating. Induction Furnace can be used to smelt iron and steel, zinc, aluminum, and desirable metal, from less than one kg to a hundred metric tonnes.

The electrical induction furnace is nonetheless a melting furnace that is used for melting metal by electric currents. The induction furnace is suitable for melting and alloying a large range of metals with minimal melt losses, but little metal refinement would be feasible.

These Induction Furnace can be classified into two categories. They are:

- Core type Induction Furnace or Low frequency Induction Furnace

- Direct core type

- Indirect core type

- Vertical Core type

- Coreless type Induction Furnace or High frequency Induction Furnace

High frequency Induction Furnace

The high-frequency induction furnaces use the heat produced by eddy currents generated by a high-frequency alternating field. The inductor is usually made of copper in order to limit electric losses. Nevertheless, the inductor is in almost all cases internally water-cooled. The furnace consists of a crucible made of a suitable refractory material surrounded by a water-cooled copper coil. In this furnace type, the charge is melted by heat generated from an electric arc. The coil carries the high-frequency current of 500 to 2000 Hz.

The alternating magnetic field produced by the high-frequency current induces powerful eddy currents in the charge resulting in very fast heating. Various configurations are available, with two or three electrodes’ high melting capacity (25 to 50 tons/hr) and they are used primarily for casting steel.

These currents also provide a certain amount of agitation to the melting charge resulting inefficient mixing. Molten metal can be poured by tilting the furnace.

Coreless induction furnaces power supply system

Power is derived from the ordinary supply grid for a coreless induction furnace, and its frequency is transformed by oscillators to a higher value. These oscillators can produce the order of megahertz with a very high frequency.

A transformer amplifies the AC supply and then rectifies it while using a bridge rectifier circuit. The rectification voltage shall be added to the oscillator and the high-frequency output is supplied by a power transformer to the load to be heated.

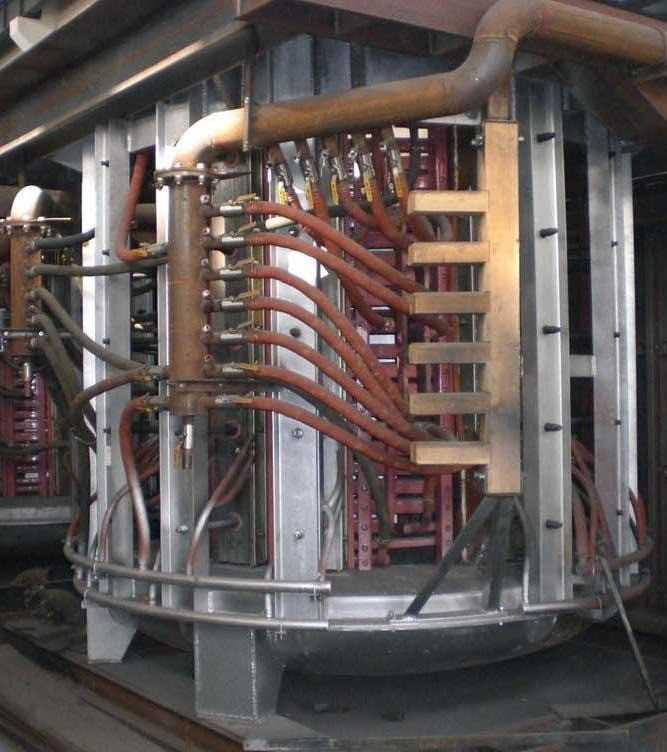

Components of a Coreless Induction Furnace

A typical coreless induction furnace consists of several key components:

Induction coil:

A water-cooled copper coil that generates the alternating magnetic field

Refractory lining:

A heat-resistant material that contains the molten metal

Power supply:

Provides high-frequency alternating current to the induction coil

Crucible:

The container in which the metal is melted

Tilting mechanism:

Allows for controlled pouring of the molten metal

Coreless Induction Furnace Melting Process

The melting process in a coreless induction furnace occurs through the following steps:

- An alternating current is passed through the induction coil, creating a rapidly changing magnetic field.

- This magnetic field induces eddy currents within the metal charge.

- The electrical resistance of the metal converts these eddy currents into heat.

- As the metal heats up, it begins to melt, starting from the outer layers and progressing inward.

- Electromagnetic stirring occurs naturally, ensuring uniform heating and mixing of the molten metal.

Cupola Furnace vs Coreless Induction Furnace

In particular for melting of high melting point alloys, the Coreless Induction Furnace effectively replenished the cupola Oven. In general, the coreless induction furnace fuses all kinds of steel and iron and even non-ferrous alloys. The furnaces have high control over temperature and chemistry, whilst the induction and frequency control circulation of the melting current and are suitable for re-melting and alloying.

Advantages of Coreless Induction Furnace:

- Induction furnace does not need electrodes like an electric arc furnace.

- Better control of temperature

- Better control of the composition of the melt

Disadvantages of Coreless Induction Furnace:

- An induction installation usually implies a big investment that must be considered and compared to alternative heating techniques.

- Induction heating is preferably used for heating relatively simple shapes.

Materials to be casted in Coreless Induction Furnace:

Conclusion

Coreless induction furnaces have revolutionized the metal melting industry, offering unparalleled efficiency, precision, and environmental benefits. As technology continues to advance, these furnaces will play an increasingly crucial role in meeting the demanding requirements of modern metallurgy and manufacturing. By understanding the principles, advantages, and future trends of coreless induction furnaces, industry professionals can make informed decisions to optimize their melting processes and stay competitive in an ever-evolving market.