What Are Automobile Brakes?

Automobile Brakes are one of the key player devices and most frequently used components in Automobile. They are used to control the motion of automobile that are required to obtain reduction in speed of vehicle or to bring the vehicle to rest. The main objectives of brakes are to stop the vehicle within shortest distance possible and to keep or hold the vehicle out of damage or danger while moving down the hill.

Braking is obtained by conversion of kinetic energy possessed by vehicle into heat energy. The resulting heat is dissipated into surrounding ambient air. Wheel skidding factors influencing braking effect in different types of brakes are mechanical shoe brake, hydraulically operated brakes, and air brakes.

Also Read

Moreover, the main aim of an automobile brake is to stop the vehicle within short distances in emergency cases. In this case, the brakes applied by producing large torques on the brake drum. While coming down from hill, to hold or keep the vehicle out of danger.

Classifications of Automobile Brakes

The automobile brakes are generally classified into different types according to few factors, the classifications according to factors are

- With respect to the number of wheels

- Two wheel

- Four wheel

- More than four wheel

- With respect to the method of braking contact

- Internal expanding brakes

- External contracting brakes

- With respect of application

- Foot brake

- Hand break

- With respect to the brake gear

- Mechanical brakes

- Power brakes

- With respect to the nature of power

- Vacuum brakes

- Air brakes

- Electric brakes

- With respect to application of braking force

- Single acting brakes

- Double acting brakes

According to the classifications, the Automobile brakes are 4 main types generally, they are

- External Contracting Brakes

- Internal Expanding Brakes

- Hydraulic Brakes

- Air Brakes

1. External Contracting Brakes

These types of brakes are sometimes used for parking on motor vehicles, cranes and for controlling the speed of auxiliary equipment drive shaft.

- The brake band or shoe of an external contracting brake is tightened around the rotating drum by using a brake lever.

- The brake bank is made of comparatively thin, flexible steel, shaped to fit the drum with a frictional lining riveted to the inner surface.

- This flexible band cannot withstand the high pressure required to produce the friction, needed to stop a heavily loaded or fast moving vehicle. But, it works well as a parking brake or hold brake.

- The brake band is anchored opposite to the point, where the pressure is applied. In addition to supporting the band, the anchor allows adjustment of the brake lining clearance.

- Other adjusting screws and both are provided at the ends of the band.

2. Internal Expanding Brakes

These types of brakes are commonly as wheel brakes, but can be found on some cranes. This type of brakes permits a more compact and economical construction.

- The brake shoes and brake operating mechanism are supported on a braking plate by brake shield attached to vehicle axle.

- The brake drum, which is attached to rotating wheel acts as a cover for the shoe and operating mechanism and furnishes a frictional surface for the brake shoes.

- The brake shoe of an internal expanding brake is forced outward against the drum to produce the braking action.

- Once end of the shoe is hinged to the braking plate by an anchor pin, while the other end is unattached and can be moved with support by the operating mechanism.

- When operating mechanism force is applied to the unattached end of the shoe, the shoe expands and brakes are applied on the wheel.

- A retracting spring returns the shoe to the original position when braking action is not required.

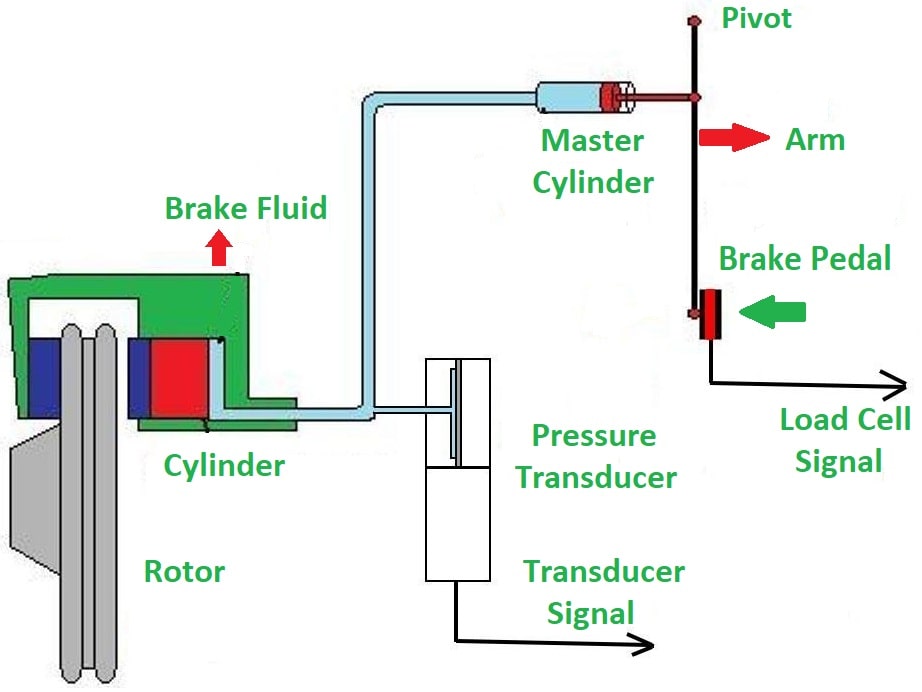

3. Hydraulic Brakes

The brakes which operate under liquid pressure are called hydraulic brakes. This brake system works on Pascal’s Principle, which states that the confined liquid transmits pressure without loss equally in all directions.

- The brake pedal is connected to the master cylinder through linkages. When brake is pressed, the piston forces the fluid into master cylinder. Therefore, the pressure of fluid increases into system.

- This pressure is transmitted to each wheel cylinder. Thereby, causing the pistons to move outwards, which forces out the brake against the brake drum or hub. Therefore, the brakes are applied.

- When the pedal is released, there is a pressure drop in the master cylinder due to which the pressure drop in the master cylinder and also there is pressure decrease in the entire hydraulic system. Hence, the brake shoes get out of contact with hub or drum. Therefore, the pistons get settled in their actual positions due to retracting spring force. Thus brakes are released.

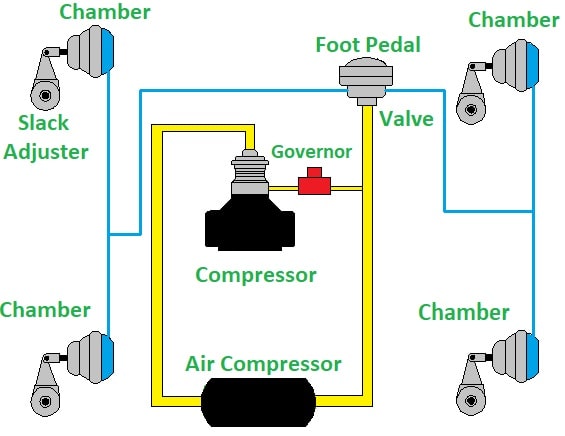

4. Air Brake

The brake in which the braking medium is air, are called Air Brakes or Pneumatic Brakes.

- Air is used to apply braking force to the brake shoes. Hence, they are also called air brakes.

- The air may be either compressed above atmospheric pressure. An air brake system includes air compressor unit.

- To maintain air pressure in the tanks, the air compressor which is a small air pump is used. Atmospheric air enters into the compressor through an air filter.

- Compressor which is activated by the engine, forces the air under pressure through water into air reservoir.

- Un-loader valve is set to a pre-determined reservoir pressure; whenever reservoir pressure reaches the preset pressure, un-loader valve retrieve the compressor and when reservoir pressure falls below the desired limits, it connects the compressor with reservoir.

- The pressure gauge indicates the air pressure in the reservoir containing enough compressed air for reversal braking operation from reservoir, the air is supplied to the brake valve.

- The brake valves present the pressure of air to the brake chambers when the brake is not depressed. Hence there is no braking effect. But when the pedal is depressed the position of the brake valves changes and compressed air is admitted into the wheel brake chambers.

- In the chambers, the air acts upon flexible diaphragms moves, then pushes out of the rods connected with the levers of the brakes gear cam.

- When the cam turns shoes are separated, thus causing the braking action.

- Pneumatic brakes are used in trucks, buses, and other HCVs, etc.

Also Read

Requirements of Automobile Brakes

- The automobile brakes should be able to stop and the vehicle in a shortest distance

- It should have smooth retardation and should be free from jerk or shudder

- The rate of retardation should be proportional to pedal effort.

- It should have less wear and tear

- It should be able to work properly in all weather conditions

- The life of automobile brakes should be more and economical

Advantages of Automobile Brakes

A. Advantages of Hydraulic Brakes

- All the four wheels are subjected to uniform braking effect due to the application of hydraulic law

- Easy to construct as there are no brake rod joints etc.

- Wear of the parts is less compared to mechanical brakes

- Self lubricating types of system

B. Advantages of Air Brakes

- These are highly powerful brakes compared to hydraulic and mechanical brakes

- They find most of the applications in heavy duty vehicles

- Design of chassis provided with air brakes is simple fittings

- The compressed air stored in the reservoir is also used incase of type of inflation, winds screen wipers, horns, etc.

C. Advantages of Drum Brakes

- The cost of spares are economical

- Thin types of brakes are depends on lining shoes

Disadvantages of Automobile Brakes

A. Disadvantages of Hydraulic Brakes

- Leakage of air causes failure of the system

- Only periodical application of brakes is possible

B. Disadvantages of Air Brakes

- Air brakes spares are generally cost more

- Air brakes system systematically arranged by valves

- It depends on compress air. If they are any leakage, system will be damaged

- Maintenance and repair costs more.

C. Disadvantages of Drum Brakes

- The shoes are glassing on surface so, cannot get rid easily

- Sometimes shoes are damaged drum internal surface

Frequently Asked Questions

1. What are mainly useful types of brakes?

The mainly useful types of automobile brakes are

- Service Brakes

- Emergency Brakes

- Parking Brakes

2. Which is better brake hydraulic or air braking?

Air brakes are very easy to connect than hydraulic brakes and using air instead of hydraulic fluid prevents many potential malfunctions.