CNC Machines and CNC Programming:

Set foot in any of the modern manufacturing companies, and you’ll find a number of CNC machines. Computer numeric control (CNC) machines, crucial for machining and automation, have become an important part of the manufacturing industry. When there were no CNC machines, the manufacturing processes would involve a huge waste of materials, a lot of human labour, and long production periods. However, the introduction of CNC machining takes a lot of burden off your shoulders, making iterative processes automatic.

CNC machines are playing an important role in Industry 3.0. In the Third Industrial Revolution, intelligent machines are replacing human work. Also, these smart machines are helping to increase overall productivity and reduce waste.

But what are CNC machines exactly? How does CNC machining work, and what is the role of CNC programming? In this blog, we’ll dig deep into the world of CNC machines. So, let’s begin!

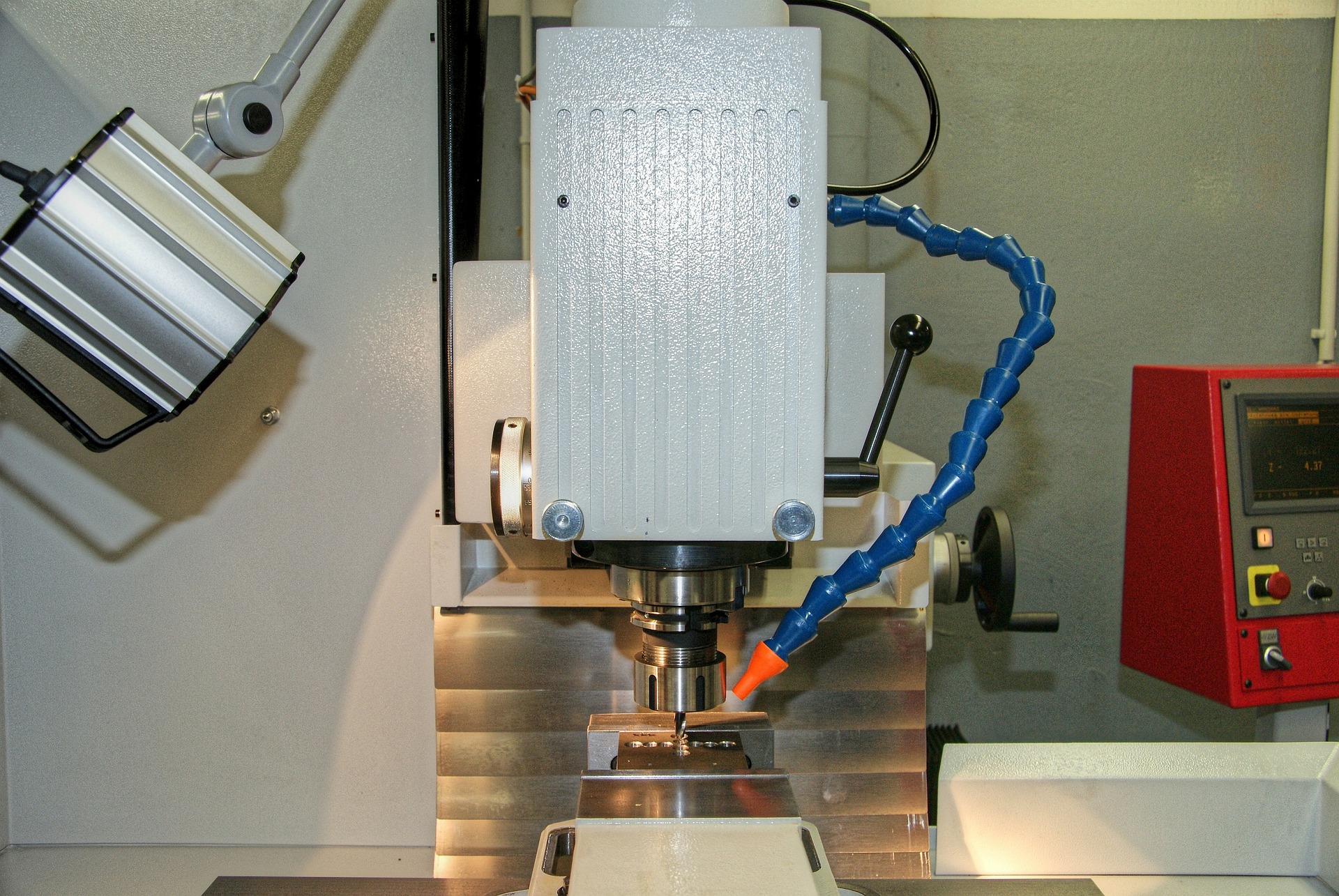

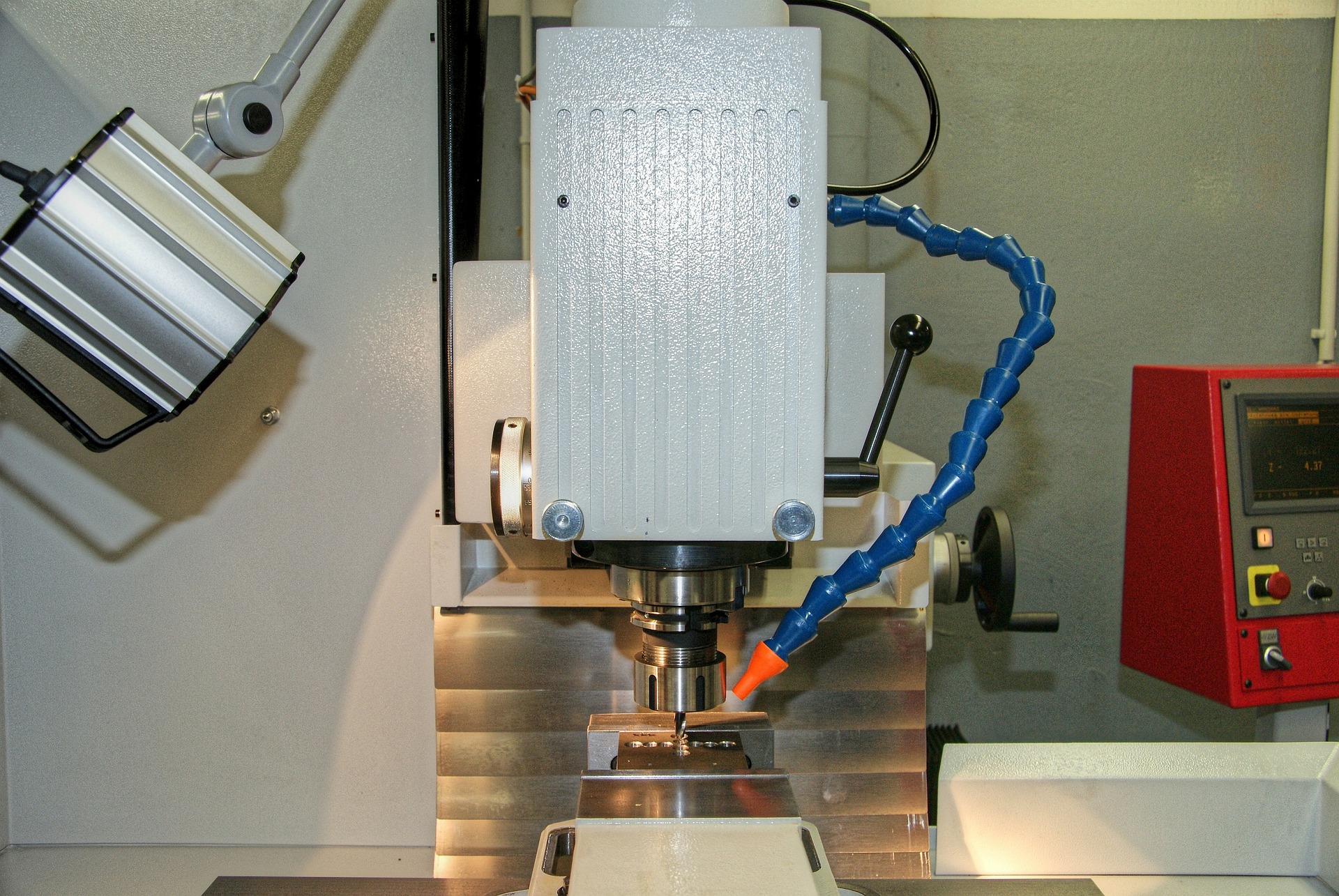

What are CNC Machines?

In simple words, CNC machines can be defined as tools that are controlled by a computer. These machines process a piece of material, like wood, plastic, or ceramic, to meet the coded, programmed instruction without requiring a manual operator. The program is either generated by CAD software or written by an expert.

Likewise, CNC machining refers to a process that takes materials away from a workpiece to meet a design. These processes utilize computerized controls to handle the machining process, resulting in the production of precise parts. CNC machines come in several varieties with different levels of complexity.

CNC machining is mainly used for its automated functionality. Nowadays, it is used for creating parts or components in almost every industry.

How does CNC Machining work?

Just like 3D printing, the CNC machining process relies on digital instructions from CAD (computer-aided design) and CAM (computer-aided manufacturing) files. First, CAD software is used to create a 3D model of the part that has been designed. After the model is approved, it is transferred to the CAM software. Then, the CAM program uses the 3D design to create a tool path for CNC. Finally, the CAM software feeds the CNC instructions to kick start the machining process.

CNC machining automates strenuous labor processes, making complex tasks easier. This improved productivity and efficiency. Some of the benefits of CNC machining are-

- More accurate and precise cuts.

- Automated cuts improve speed and precision.

- Quick turnarounds.

- Helps in the on-demand production of prototypes.

- Allows project completion ahead of time.

- Reduces labour costs.

- Repetitive jobs can be done with constant accuracy.

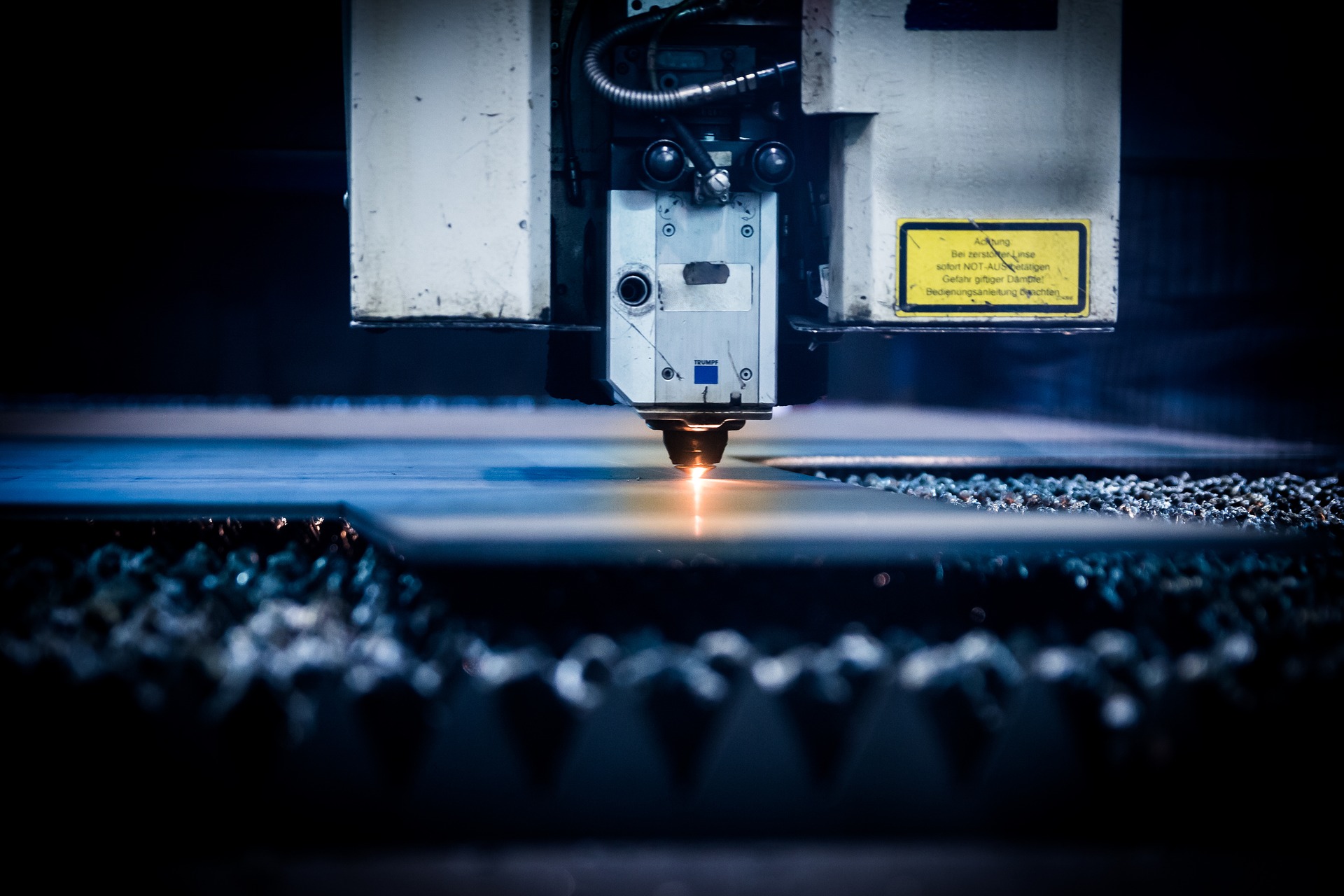

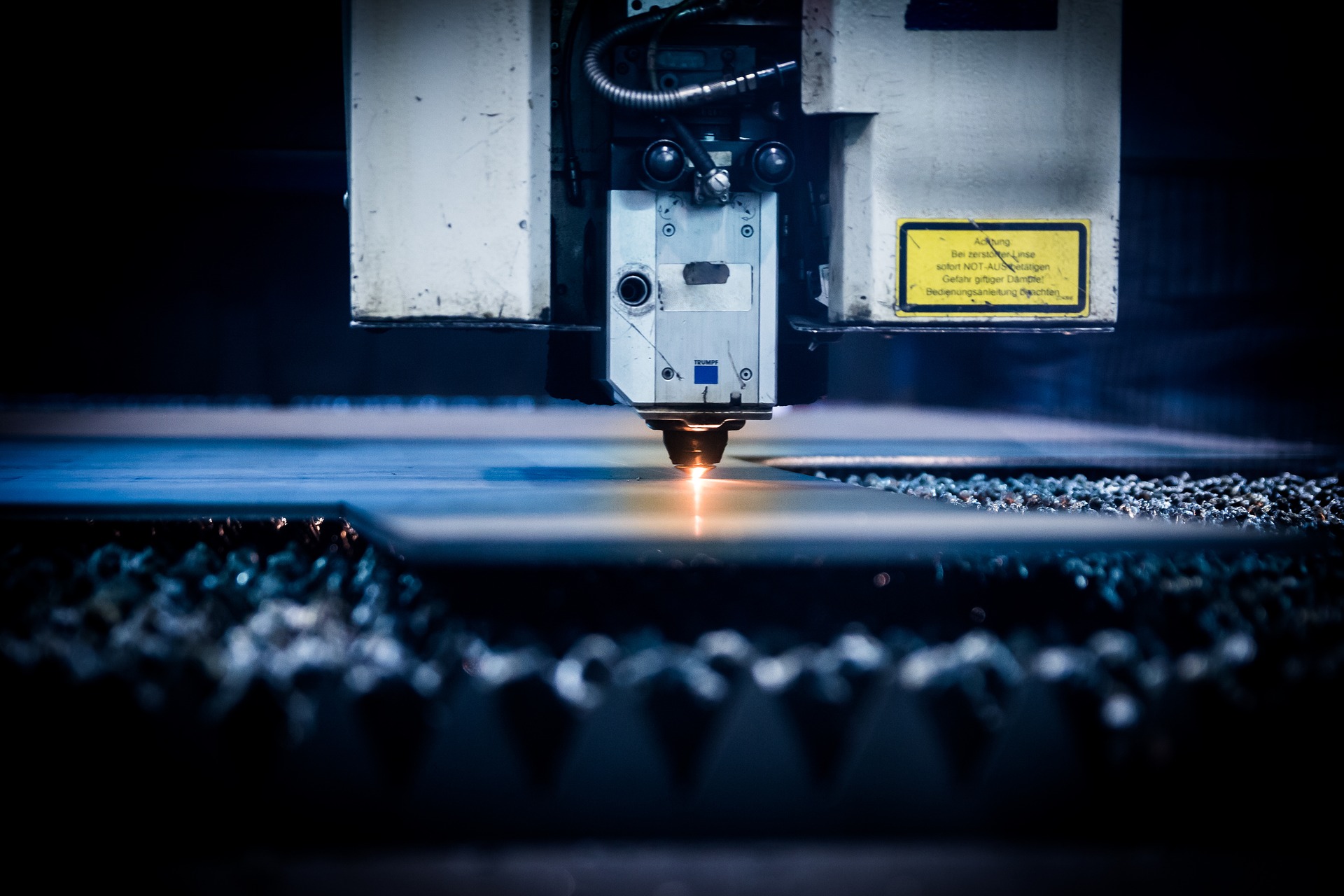

Numerical control machines were first employed in the 1940s when motors were used to control the movement of tools. Now, with advanced technologies, the mechanisms are enhanced with digital computers, giving rise to CNC machining. Some of the common CNC-operated processes are laser cutting, ultrasonic welding, etc. And the most commonly used CNC systems include CNC mills, plasma cutters, water jet cutters, electric discharge machines, etc.

CNC Machine Programming

When it comes to CNC manufacturing, CNC machines are operated through numerical controls, and a software program is designed to control an object. CNC programming relies on G-codes that are written to control the behaviour of the machine, including its coordination, speed, or feed rate. The letter ‘G’ is followed by a number, for example, G67, indicating the starting position for the program. G-code tells the CNC machines where to move the tool in order to prepare for the rest of the program.

With CNC machining, it is easy to pre-program the speed or position of different machine tool functions and operate them via software consistently.

Below are the different methods of CNC programming-

CAM Software

CAM software is a type of CAD software. Like CAD, this software also requires a computer program to design and create a set of instructions for a CNC machine.

G-Code Programming

G-code is the most basic CNC programming. In fact, G-code is used in the other two CNC programming methods. However, the other two methods are ways to work around the G-code.

Conversational Software

This software allows machine tool operators to create part programs at the machine’s control. It uses an interface to convert all commands into G-code, making the interface easier.

Also Read:

What Else Can A CNC-Programmed Machine Do?

Companies use CNC machines to make detailed cuts out of metal pieces for hardware products. Besides the machines mentioned above, you can also find other machine pieces used in CNC manufacturing too. CNC machines are mostly used in the production process of steel aerospace parts, plastic consumer goods, wooden decorations, etc. Some of the primary machinery pieces used in CNC systems include wood routers, 3D printers, embroidery machines, glass cutters, foam cutters, wire-bending machines, cylindrical grinders, and more!

This was all about CNC machine basics and CNC programming. Hopefully, now you have a good idea of what a CNC machine is and how it is advantageous to the manufacturing industry.