Quick

Overview

Simcenter offers

a dedicated application to map steady state or transient flow results

onto a target model, typically an independent structural model from the

same geometry but with a different mesh. For example, one could be

interested in the stress and distortion analysis of a canopy due to wind

forces.

The target FEM must use the same global coordinate system

as the source FEM, and both models should be geometrically congruent.

However, they need not share the same mesh. Results are mapped from the

selected solution on the source model, to a solution on the target

model, based on proximity and with optional zone associations. The

output of the mapping solution can then be used by the target solution.

In what follows, we describe how to create an NX Nastran structural analysis using forces that are mapped from a Simcenter Thermal/Flow analysis.

Workflow overview

The main steps are:

- Create

a part file containing the structure and air volume. - Create

a Simcenter Thermal/Flow fem file with only the air volume meshed. - Create

a new Simulation containing a Thermal/Flow Solution with Flow Analysis. - Run

the Thermal/Flow Solution. - Back

to the part file; create a NX Nastran fem file of the structure. - Create

a new Simulation containing a Thermal/Flow Solution with Mapping Analysis. - Specify

the mapping target area then Solve. - Assign

the structural boundary conditions and solve the structural analysis.

For more information, see

Simcenter Thermal/Flow, Electronic Systems Cooling, and Space Systems Thermal

documentation.

Create the Thermal/Flow Simulation

1.

Create the part

We begin by creating the part

file, as shown in Figure

1.

This represents a simple tubular structure submitted to lateral winds.

Figure 1: Part file containing both structure

and fluid volume

2.

Create the Thermal/Flow FEM

Next, create the fem file. In the

“Edit FEM” window, make sure to choose Simcenter Thermal/Flow (Flow) as the “Solver

Environment”, as shown in Figure

2.

Figure 2: Creating the Thermal/Flow fem

Then create a 3D mesh for the air

volume, as shown in Figure

3.

Figure 3: Mesh the air volume only. The

structure is not meshed.

3.

Create the Flow Solution

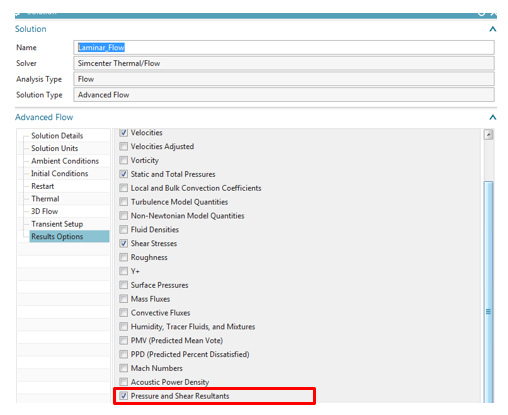

We now create the “Simulation”

file, and define a “Flow” analysis. As shown in Figure

4,

define a non-turbulent transient analysis. Furthermore, in the “Result

Options”, see Figure

5,

check the “Pressure and Shear Resultants” box – these will be used for the

mapping step.

Then, edit the “Transient Setup”

tab as illustrated in Figure

5.

Figure 5: Results Options for flow forces

Figure 6:

Transient setup options

4.

Apply the boundary conditions.

Three boundary conditions are

applied:

- An inlet of 30 mm/sec at ambient conditions on

the –Y faces. - An opening at ambient conditions on the +Y faces.

- Slip walls to represent an extended fluid domain

on the +X, -X and +Z faces.

As nothing is prescribed on the

bottom surface, the solver automatically assumes no-slip, which represents a

solid surface. Boundary conditions are shown in Figure

7.

We now solve this Flow solution. An

example of the flow velocity profiles is shown in Figure

8.

Figure 8: Flow velocity profile.

Mapping the flow forces

1.

Create the structural mesh

Starting with the same part

created in step 1, create a new fem file. In the “Edit FEM” window, make sure

to choose the NX Nastran (Structural) “Solver Environment”, as shown in Figure

9.

Figure 9: Creating the Structure fem

This time, we will only mesh the

structure component and ignore the air volume. See Figure

10.

An aluminum material is assigned to the tube.

Figure 10: Structure mesh only. The air volume

is not meshed.

2.

Create the Mapping Solution

To map the flow forces to the

structural analysis, create a new “Simulation” file and choose a “Thermal-Flow”

Solution with a “Mapping” type, as shown in Figure

11.

If you leave the “Transient Times” table empty, the solver automatically

selects all transient time steps from the flow solution.

Figure 11: Create a Mapping Solution

Next, in the “Optional

Output” tab, check the boxes shown in Figure

12

to create the mapping and target Nastran structural solution. A static solution

is created. This type of analysis is valid when inertial effects are negligible

and where the dynamic content of the flow pressures is well separated from the

structures principal modes.

Figure 12: Creating the Mapping and Nastran Solution

3.

Solve the Mapping Solution

Before solving the Mapping

Solution, we define a “Mapping Target Set”. This defines the surfaces on which the

flow forces will be mapped. Select the cylindrical face of the tube and its free

face, as shown in Figure

13

and Figure

14.

We can now solve the Mapping Solution. An example of the mapped forces at a

given time step is shown in Figure 15.

Figure 14: Select the mapped surfaces

Figure 15: Example of mapped forces

4.

Solve the structural solution

The “Simulation Navigator” now

shows one subcase corresponding to each transient time step of the flow

solution. See Figure

16.

Figure 16: Subcase created for each transient

time step of the flow solution

Before solving, we fix the

translational degrees of freedom on the –X face of the tube. Solve the

solution.

5.

View displacement results

Next, select a subcase and display

the displacement results, as shown in Figure

17.

The deformed structure is shown together with the undeformed mesh in Figure

18.

Figure 17: Nodal displacement results